epoxy

-

A Race Against Time

While Dotty gets a full-body exfoliation (goodbye, rotten wood), the rest of us are practicing the fine art of pretending everything is fine. Twelve days left. No big deal. Plenty of time to rebuild, rewire, reimagine, and lose the last remaining shreds of sanity. Everything is definitely under control. It’s fine. It’s fine.

-

Middle of the night truckstop shantyboat repair

Middle of the night truckstop epoxy work to repair the damaged hull of the shantyboat. #epoxy #boatrepair #shantyboat #roadtrip

-

New Boat Vocabulary Word: Coaming

One of the smarter things I’ve done on the shantyboat, was to add a coaming around the edge of the cabin. A new vocab word for me as I slowly get all nautical during the one plus year shantyboat build: coam·ing /ˈkōmiNG/ Noun A raised border around a ship’s hatch serving to support the hatch…

-

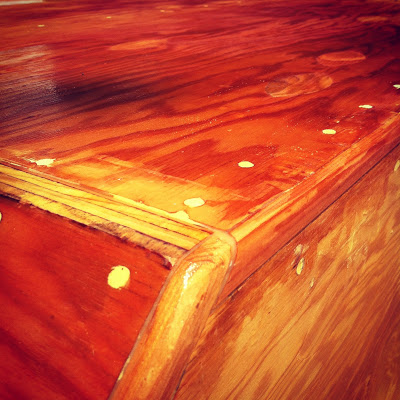

Obsessive woodworking, top side

With both decks on, I could be an obsessive woodworker again. First I shimmed up any really large gaps with thin pieces of wood, epoxying them on. Then I routed all the edges. Once I sanded down the bumps and the previous coat of fiberglass, there were still some larger structural gaps that I wanted…

-

Installing the aft deck

I put the aft deck on. Thought you should know. There were some awkward places in the aft section of the boat where the stringers didn’t quite line up. One stringer dipped lower than the rest. So I had to add on little thin wedges of wood to the tops of the members. I am…

-

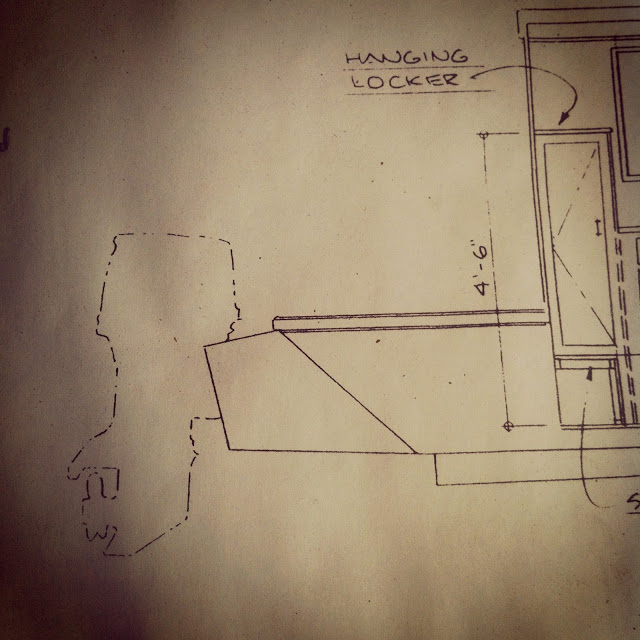

Motor Well, A Mini-Project Unto Itself

Oh, the motor well. Seems simple enough. Build a box that bolts to the back of the boat, upon which the motor clamps. I’ve been working on the motor well since the days of the Troublesome Skegs and before the Boat Flip. Turns out that though this earns only a brief paragraph in the Glen-L…

-

A Front Deck and Photos of an Adorable Puppy

First off, now that the boat is upright, I made Hazel a ramp so she can go in and out of the boat while I’m working. Next, I put the front deck on. There are probably things I need to do under there that would be easier without the deck, but my excitement trumps good…

-

Fiberglass Bond Coat

Okay, so let’s review. Fiberglass (of more accurately glass-fiber reinforced plastic) is a composite laminate of hardening plastic goo reinforced with Ziggy Stardust-esque silvery spun glass fabric. We have already applied the “seal coat” and need another several layers before we’re done. I found the Glen-L instructions for applying fiberglass for you. This is pretty…

-

Fiberglass Seal Coat

We fretted over fiberglassing the hull so much, we put off beginning with this step for weeks. We read and reread our instructions from Glen-L, Ken Hankinson Fiberglass Boatbuilding book, and anything else we could find. We went over scenarios and thought of terrible things that could go wrong. We thought it would be so harrowing…

-

Hockey Puck Manufacture (or Epoxy is Stressful II)

Did I mention that epoxy is stressful? To recap: You have 15 to 30 minutes to get a bucket full of epoxy mixed, applied, and secured down before it turns into a rock-hard mistake that must be laboriously chipped, chiseled, and sanded off. Add to that, less than ideal conditions of 95°F days and adding…

-

Hull Finish Work (or Correcting Mistakes III)

I like to joke that I bring Old World Craftsmanship to my work. Old World like Neanderthal, the fine kind of workmanship you get from precision woodworking tools such as heavy clubs and sharpish rocks. One of the things I like about building is all the layers of increasingly fine-tuned craftsmanship one brings to a…

-

Hull Ends

Oh god, at the end of every work day when we are high-fiving each other, we are always marveling at just how much more boatlike the boat looks. But today, for reals, at the end of the work day, the boat doesn’t just look boatlike — technically if you dropped it in the water, it…

-

Sheeting the Hull

It looks easy, right? What could go wrong? Four rectangular sheets of plywood lined up together on a horizontal surface made to fit them, screwed down on all the edges. But as soon as we started sheeting the bottom of the boat, we realized this seemingly simple task would be more complicated. How do we…

-

Correcting Mistakes I

Today, the chickens come home to roost. Remember that pesky three degree error? As we assembled each of the stringers, we could see that the pieces didn’t come together quite right. It would have been laborious but simple enough to cut new ones, but oh no. I figured I could just cheat the difference on…

-

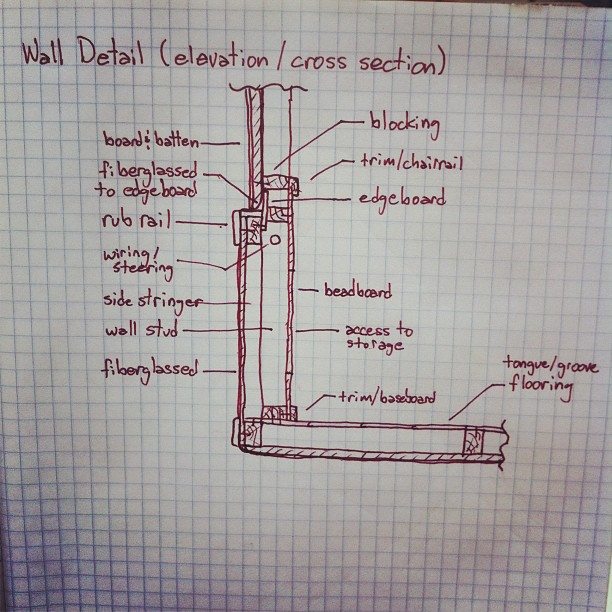

Side Stringers

The side stringers are the sides of the boat. So far everything we’ve been doing was stuff inside; here we finally tackle something that will ultimately keep water out. Yikes! And because of the complexity of the build and our boat-tardedness, it took us about seven hours per side to assemble. In our last build…

-

Keel and Skeg Stringers

It most conventionally built wooden boats, the frames refer to what you might think of as the “ribs” of the boat running across ways (that’s “athwartship,” to you, matey!). In the Glen-L Waterlodge, the framing members run longitudinally and are called stringers. So building the boat frame means assembling the individual stringers and then tying…

-

Epoxy is Stressful

You know the scene at the end of any action movie where the hero has minutes to disarm the bomb, cutting the wires in just the right sequence or he blows up the 747 full of schoolkids? Working with epoxy is just like that. In short, using epoxy involves mixing two dangerous chemicals together to…