boat building

-

Shantyboat on the Mississippi

In July, we are bringing the shantyboat across country to launch in the Mississippi River on an art and history expedition: Thanks to espressobuzz for the historic photo A journey to rediscover the lost narratives of river people, river communities, and the river itself. Secret History is an anthro-historical artist’s journey through the history of…

-

What the #*@&% happened?

You must hate me. Last I left you with “Walls take shape” and then radio silence for six months. Did I lose interest in the project? Get tragically killed by a falling jet engine? No, I’m not dead and the project is moving along albeit a little more slowly. I started grad school. Which means…

-

Roof Rafters – The cabin takes shape

When we disassembled the Hollister chicken coop, we got a bunch of beautiful old 1×12 redwood siding, a shitton of corrugated metal, a handful of old dimensional redwood 2x4s, and finally, a dozen or so roof rafters, complete with birdsmouths. True they were old and some were a little worse for wear, rotted at the…

-

Cabin Framing, More Mistakes Were Made

If there’s one thing I’m good at, it’s not being good as things. But given my delightfully blinding optimism, I plunge on ahead anyway, learning a ton with each monumental goof. You remember the cabin framing looked like this. That’s more or less an eight foot wall, with maybe 1 foot 8 inches below the…

-

Cabin Wall Framing. Finally.

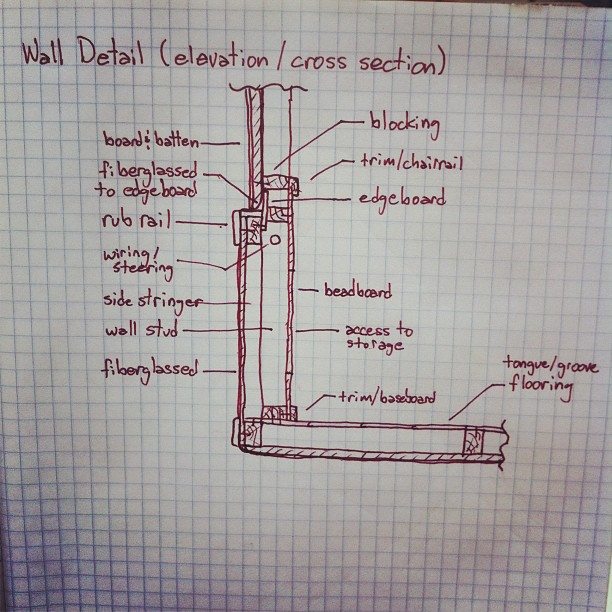

Whew, finally. We get to constructing the cabin walls. This is the fun part for me. As a former carpenter, framing construction is well-within my comfort zone. Initially, it looked like it would be easy as pie. I planned to simplify the standard stud construction to reduce weight: (single) sole plate + studs + (single) top plate +…

-

New Boat Vocabulary Word: Coaming

One of the smarter things I’ve done on the shantyboat, was to add a coaming around the edge of the cabin. A new vocab word for me as I slowly get all nautical during the one plus year shantyboat build: coam·ing /ˈkōmiNG/ Noun A raised border around a ship’s hatch serving to support the hatch…

-

A Collection of Photos from a Non-Shantyboat River Float

I took a two-week break from building the shantyboat to float the Sacramento River. I post this here, because floating on these big rivers is where I got the craving for living on a shantyboat. Some of my favorite times are from drifting aimlessly in our DIY raft during hot summer days. These rafts were…

-

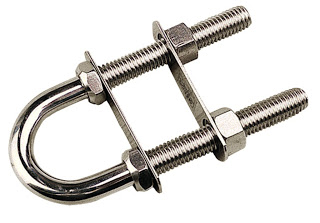

Bow Eyes and Stern Tiedowns

Sometimes little things can be a big headache. And sometimes big headaches can turn out not to be that big a deal at all. And so it was with the bow eyes and stern tiedowns. Here’s the idea, I have a trailerable shantyboat. It is really really nice if when I am towing down the…

-

The Cabin Has a Floor

Let’s put in a floor! This is the floor that will be inside the cabin. Remember the beautiful old redwood I got from the chicken shed that Jen, Kai, Alex and I salvaged last year? I wanted to use these thick 1x12s for flooring in the boat. The also have the advantage of putting some weight…

-

Obsessive woodworking, top side

With both decks on, I could be an obsessive woodworker again. First I shimmed up any really large gaps with thin pieces of wood, epoxying them on. Then I routed all the edges. Once I sanded down the bumps and the previous coat of fiberglass, there were still some larger structural gaps that I wanted…

-

Installing the aft deck

I put the aft deck on. Thought you should know. There were some awkward places in the aft section of the boat where the stringers didn’t quite line up. One stringer dipped lower than the rest. So I had to add on little thin wedges of wood to the tops of the members. I am…

-

Motor Well, A Mini-Project Unto Itself

Oh, the motor well. Seems simple enough. Build a box that bolts to the back of the boat, upon which the motor clamps. I’ve been working on the motor well since the days of the Troublesome Skegs and before the Boat Flip. Turns out that though this earns only a brief paragraph in the Glen-L…

-

Protecting the Bilge

Water is the enemy of wood longevity. Protecting the wood inside the boat, especially in the bilge is critical. Here’s the plan, slightly ridiculous in it’s conservatism. Two coats of Copper Napthenate (Copper Green) to prevent bacterial and fungal decay. Two coats of water-based exterior latex primer. A coat of water-based exterior latex paint. First though, I wanted…

-

A Front Deck and Photos of an Adorable Puppy

First off, now that the boat is upright, I made Hazel a ramp so she can go in and out of the boat while I’m working. Next, I put the front deck on. There are probably things I need to do under there that would be easier without the deck, but my excitement trumps good…

-

More Cabin Planning

If you’ve been following the blog, you know that one place that I’m diverging from the Glen-L Waterlodge plans is in the cabin. While I have been true to the plans while building the hull, I am increasingly going off into the wild blue as I design and build the cabin. The original plans called for a…

-

A Bunch of Questions

Here’s a big pile of questions that occur to me. Solutions will no doubt present themselves, but in the meantime they are open questions. I’m not sweating the answers, but just want to remember to keep them in my mind for now. Q: How will the winch be mounted on the trailer? Q: How will…

-

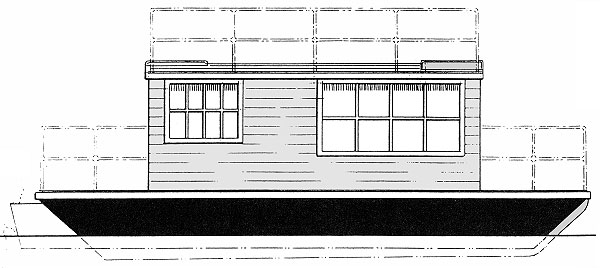

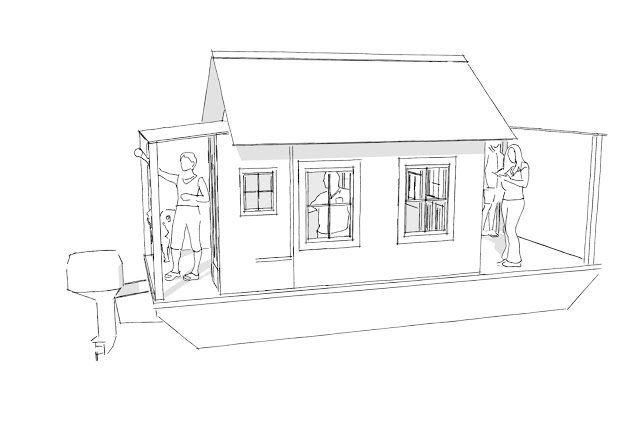

Fancy Pants New Renderings

There you go. 3D rendering doesn’t make anything more real, but it does help me understand some of the challenges I’ll face when I start constructing the cabin. New rendering, now with more Hazel dog!

-

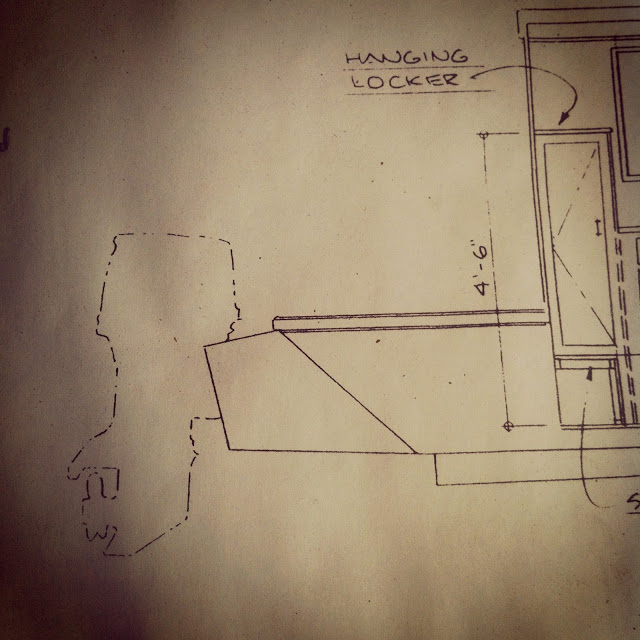

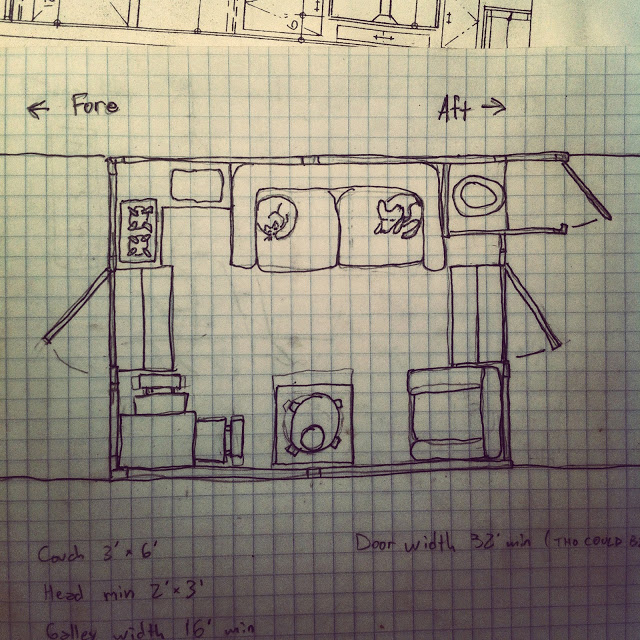

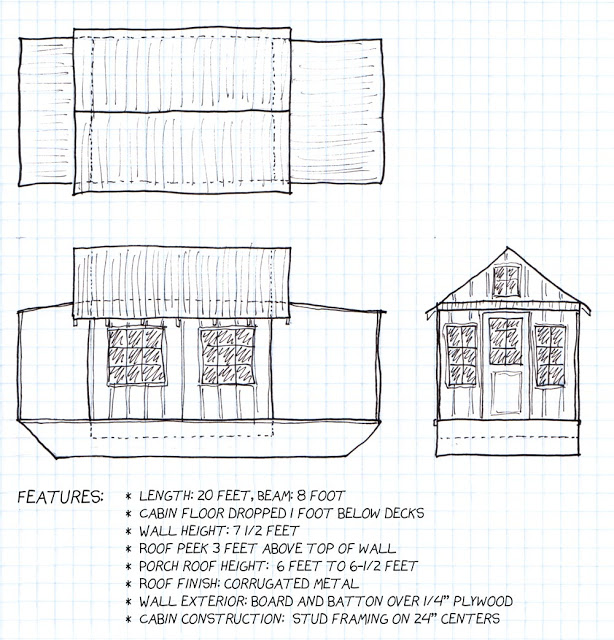

Thinking About Cabin Construction

Now that the boat is ready to be flipped, I’m thinking again about the cabin. Here’s the plan, in general, for the completed shantyboat. I’d been giving some thought earlier to the cabin layout, but finally sat down and planned everything out using real measurement. In clockwise order from top left: Small galley with 2-burner…

-

Welding the Trailer

Timeline: Less than a week before the boat flip! The trailer needs several repair welds to make it safe. The clock is ticking. I got a recommendation for a welder from the same awesome friend at the lumberyard who sold me the skids. I called the guy on an odd Thursday that I was playing…

-

And now back to the trailer

Remember the trailer? This one, the one that almost killed us? We left the shantyboat hull pretty complete. Now that the boat is ready to be flipped, we turn our attention back to the trailer. It is really a rusty, janky old thing. I’ve owned it for fifteen years or so, or sorta owned it since…

-

The Talented Mr. Johnson

For a while now, my cousin Brian has been wanting to introduce me to Mr. Johnson. He’s had Mr. Johnson living with him for a time and thinks he’ll be just the person to help get my shantyboat project going. I’d been thinking about powering this little craft, particularly as I put the finishing touches…

-

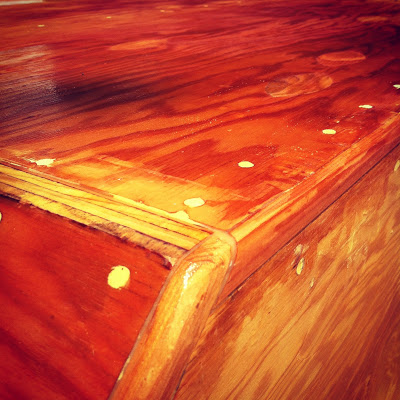

Those Troublesome Skegs, Finishing Touches

So the skegs are mounted, but the carriage bolt countersinks are still there. Let’s fix that. I bought a hardwood dowel of the same diameter as my countersink holes. Happily, the grain ran crossways the length of the dowel, making sweet little plugs when I cut little coins off the end. A story in pictures.…

-

Those Troublesome Skegs, Mistakes Were Made

So the skegs have been cut, spliced, drilled, countersunk, stained, and finished. Now we only have to mount them. Easy, right? Ahem. I looked for a long time to find just the right sealant and adhesive for the skegs. They get bolted down of course, but you have to seal them really well, both to…

-

Those Troublesome Skegs, Bolt Holes and Finish

Here we drill all sorts of holes in our newly made skegs and finish them. You know, it really helps to have the right tools. And you know what helps having the right tools? Money. I don’t got none of that, so I have to make do with the tools I have. And sometimes that…

-

Those Troublesome Skegs, Scarf Joints

I had to turn 14 foot pieces of lumber into 16 foot lengths for the bottom skegs. To do this we use a scarf joint. According to wikipedia: The joint is formed by cutting opposing tapered ends on each member which are then fitted together. When working with wood, this gives better long grain to…

-

Those Troublesome Skegs, Part the First

When we built punk rafts and floated several big rivers, we powered the rafts with canoe paddles and our own arms. Though the big innertubes that floated the rafts provided so much flotation, they drew no more than a few inches of water, it was still like pushing a truck. After a long day of…

-

Hull UV Protection

Fiberglass over plywood is ridiculously tough. There are wood and fiberglass boats still around after 50 years. However, fiberglass has an Achillis Heel — sunshine. Fiberglass rapidly degrades with exposure to UV rays. Thus, it is recommended to paint or varnish fiberglass with something offering UV protection. We wanted the boat to show off it’s…

-

Fiberglass Finish Coats

After the fill coat, the texture of the fiberglass cloth was still visible, so we embarked on a series of finish coats. I think we finally put three more coats on after the fill coat. The Finish Coat, the Aren’t We Done Yet Coat, and the Good Lord Please Let This Be The Last Coat. …

-

Fiberglass Fill Coat

At this point, we have the fiberglass bonded to the boat with a layer of epoxy. The texture of the cloth is still quite visible, so we have to add enough epoxy that it is invisibly hidden. Since by now we are grizzled veterans of fiberglassing, the work was not so stressful and only required…

-

Fiberglass Bond Coat

Okay, so let’s review. Fiberglass (of more accurately glass-fiber reinforced plastic) is a composite laminate of hardening plastic goo reinforced with Ziggy Stardust-esque silvery spun glass fabric. We have already applied the “seal coat” and need another several layers before we’re done. I found the Glen-L instructions for applying fiberglass for you. This is pretty…

-

Fiberglass Seal Coat

We fretted over fiberglassing the hull so much, we put off beginning with this step for weeks. We read and reread our instructions from Glen-L, Ken Hankinson Fiberglass Boatbuilding book, and anything else we could find. We went over scenarios and thought of terrible things that could go wrong. We thought it would be so harrowing…

-

Hockey Puck Manufacture (or Epoxy is Stressful II)

Did I mention that epoxy is stressful? To recap: You have 15 to 30 minutes to get a bucket full of epoxy mixed, applied, and secured down before it turns into a rock-hard mistake that must be laboriously chipped, chiseled, and sanded off. Add to that, less than ideal conditions of 95°F days and adding…

-

Opinions are like assholes…

Everyone’s got one. Every now and then I’ll ask a boat-related question on a public forum or email list. It sure isn’t a problem getting people to weigh in with their opinion, that’s for sure. The challenge, actually, is picking through the dross of misunderstanding, inaccurate information, speculation, and completely made-up answers to find the…

-

Hull Finish Work (or Correcting Mistakes III)

I like to joke that I bring Old World Craftsmanship to my work. Old World like Neanderthal, the fine kind of workmanship you get from precision woodworking tools such as heavy clubs and sharpish rocks. One of the things I like about building is all the layers of increasingly fine-tuned craftsmanship one brings to a…

-

Hull Ends

Oh god, at the end of every work day when we are high-fiving each other, we are always marveling at just how much more boatlike the boat looks. But today, for reals, at the end of the work day, the boat doesn’t just look boatlike — technically if you dropped it in the water, it…

-

Sheeting the Hull

It looks easy, right? What could go wrong? Four rectangular sheets of plywood lined up together on a horizontal surface made to fit them, screwed down on all the edges. But as soon as we started sheeting the bottom of the boat, we realized this seemingly simple task would be more complicated. How do we…

-

Correcting Mistakes II: The Usefulness of Square Corners

When we went to put sheets of plywood on the top, er, bottom of the boat hull, they didn’t really line up. WTF? It seemed unlikely that four sheets of plywood were manufactured not quite square, so we had to look elsewhere. When we assembled the stringers with the cross beams, we had squared the…

-

Correcting Mistakes I

Today, the chickens come home to roost. Remember that pesky three degree error? As we assembled each of the stringers, we could see that the pieces didn’t come together quite right. It would have been laborious but simple enough to cut new ones, but oh no. I figured I could just cheat the difference on…

-

Cross beams

This was an exciting day because for the first time, the boat was one piece. Not just a pile of lumber. Not just a bunch of stringers. But one single solid piece that was even boat shaped. More or less. Earlier when we were making the pieces for the stringers we trimmed a bunch of…

-

Side Stringers

The side stringers are the sides of the boat. So far everything we’ve been doing was stuff inside; here we finally tackle something that will ultimately keep water out. Yikes! And because of the complexity of the build and our boat-tardedness, it took us about seven hours per side to assemble. In our last build…

-

Keel and Skeg Stringers

It most conventionally built wooden boats, the frames refer to what you might think of as the “ribs” of the boat running across ways (that’s “athwartship,” to you, matey!). In the Glen-L Waterlodge, the framing members run longitudinally and are called stringers. So building the boat frame means assembling the individual stringers and then tying…

-

Epoxy is Stressful

You know the scene at the end of any action movie where the hero has minutes to disarm the bomb, cutting the wires in just the right sequence or he blows up the 747 full of schoolkids? Working with epoxy is just like that. In short, using epoxy involves mixing two dangerous chemicals together to…

-

Angles and Precision

I have experience in the housebuilding, construction world. I used to joke with my workers when they’d talk about measurement in sixteenths. “Sixteenths? I didn’t know they made fractions smaller than eighths.” And in homebuilding, unless you are a finish carpenter, there is seldom need to take such fine measurements. Not so much in building…

-

Making Sawdust

The whole process of building a boat involves cutting a lot of lumber, but at the beginning there were whole days of doing nothing but. The plans called for kiln-dried or air-dried lumber of no more than 12% moisture. I live in the hills of Northern California which at times is like living in a…

-

Organization: How To Make Boatbuilding Not Suck

Boats are made of lots and lots of funny precision parts that all look more or less the same but are subtle different. A bow skeg stringer end accidentally exchanged for a stern skeg stringer end and it’s all over. The previous build day, in my excitement I threw together the dead simple building form,…

-

First Build Day: Building Form

After months of hemming and hawing over plans and possibilities and uncertainties and even driving to the Middle of Nowhere to get a trailer, finally we start building the boat. Or at least we build something that is essential for building the boat. The Glen-L plans call for making a building form upon which to…

-

Questions for the Old Man

I didn’t expect myself to be talking to the old man, the designer himself, bouncing my dumb ideas off him and hearing the edge of concern in his voice. I bought our Shantyboat plans from Glen-L Marine. The company was started by and named after Glen L. Witt, a boat designer who’s been designing boats…

-

Boat Plans: Choices Made and Not Made

So it looks like we’re building a boat. Not merely throwing a bunch of shit on the deck of a couple pontoons, or strapping a bunch of barrels together, but making a boat. You know, one of those things that floats in the water and has things like a hull and a deck, not to…

-

Boating errand in the flattest dryest spot in North America

“Ha ha,” said Alex when we took off with the 20 foot flatbed, “We were worried about the trailer, but just think, my tow kit is only being held on by four bolts.” Ha ha, I said. An hour later we were heading back to Reno after a dramatic bumper removal and whiplashing trailer on…

-

Tips on how not to die in a fiery ball of twisted metal on the highway

Anyone know anything about trailer tow hardware like sway bars and weight distributing whohaws and whatnots? The shantyboat we’re planning will be trailer-able. So if I’m gonna be towing a heavy-ass boat on a trailer down the road with a 20 foot double axle trailer with electric brakes, I want not to experience the sheer…

-

Destruction and Creation

Sometimes the treasure hunt of creating something from salvaged materials is half the fun. Okay, Okay. I’ll admit it, more than half the fun. I’ve been making art out of bullshit found in junkpiles and on dump runs for more than a decade. But when you want to create a barn or a shed or…

-

Bruce’s Pontoons

We were planning to use Bruce’s pontoon boat that he scored somewhere around the Lake Shasta area as the base for our shantyboat. In fact, it was Bruce’s pontoon boat score that gave us the greenlight for this project. Not so sure about this now. Every boat has a buoyancy, a certain weight that it…

-

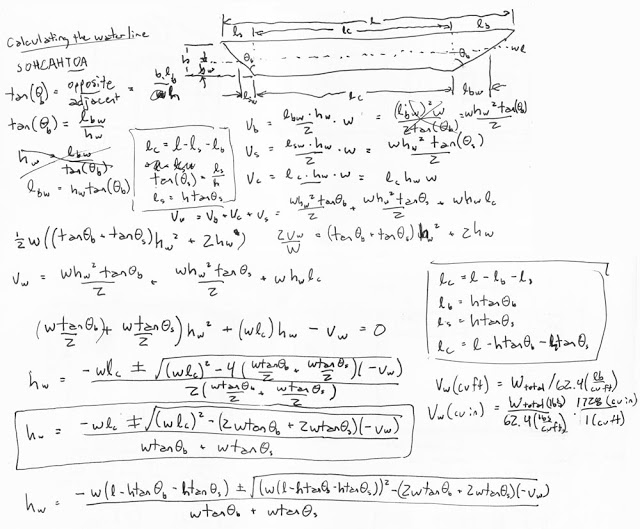

Math is Hard – Calculating a Waterline

Who would have thought boatbuilding would involve so much math? I was reading Glen L. Witt’s Boatbuilding With Plywood and realized what should have been obvious to me: The waterline of a boat is calculated beforehand. I guess it makes sense that boatbuilders don’t guesstimate their designs only to drop their boats into the water…

-

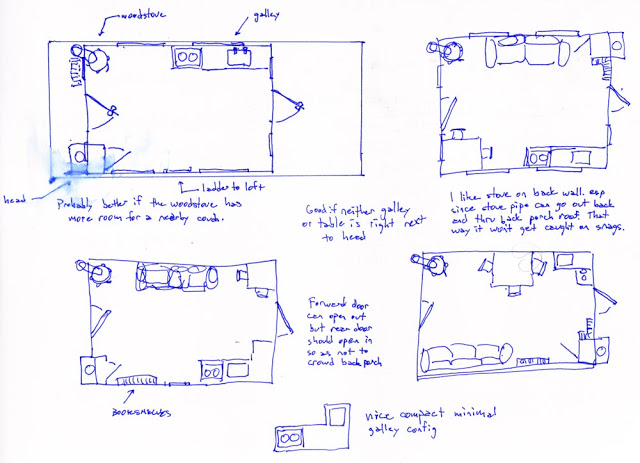

Karaoke Doodles

So far, I’ve ignored the inside cabin layout, thinking that it would sort itself out eventually. But I got thinking, and with a few beers started doodling. I went to the normally quiet Trout Farm on Zayante Road (the same road on which we will build the shantyboat). Unbeknownst to me, it was karaoke night…

-

Beyond Napkin Plans

I’m trying to turn my shantyboat speculations into something that feels a little bit more tangible. Ooo, graph paper! Getting fancy now. When I sketch it out proportionally, the shanty boat is less long and skinny than I had drawn it. In fact, it looks like a tiny shanty. On a boat. I’d kind of…

-

Folding Gable Ends

We were aware that this beast with its generously gabled roof would be pretty tall. Especially on a flatbed. So I worked on some mechanism that would allow the gabled roof to fold down flat. The question is: How can you fold down the gables and then the two roof sections without anything binding? I…

-

Boat Builder Porn

Is it hot in here, or is it just me? I spent a rainy Felton afternoon checking out shanty boat info on the World Wide Web. While there are many amazing photos and stuff, today boat plans are making me hot. Check this shit. This is the Escargot Canal Cruiser, designed by Phil Thiel of…

-

WANTED

You know how many marinas there are in the Sacramento Delta? A lot, let me tell you. And I’ve called nearly every one in search of our elusive, inexpensive junked, but still floating, 20 foot-or-so pontoon boat. A few leads which I’m following up on. Kai and I also hung a flier up in a…

-

Walls and diagonal bracing

I was worried that since we were planning to sheet only the outside with vertical boards, that the walls would have no sheer strength and would be subject to deformation by lateral forces such as wind, waves, and hitting an iceberg. Here is a suggestion from Aralia to give the walls sheer strength. We are…

-

A Madcap Boat Scavenging Journey

Kai and I took a mad motorcycle trip up the Sacramento Delta to check out a couple of “pontoon boats.” They turned out to not only not be pontoon boats, but much longer than we were told and barely afloat. The first was a fiberglass houseboat around 35 feet or so, much too large, and…

-

Inspiration

Looking around, shanty boats have been around for a long time. The dream of living on the water is hardly new. Shanty boats were the obvious choice for itinerant workers, miners, dockworkers, and farmers. And as living on land has felt more and more constrained, people have looked to the relative freedom of rivers, lakes,…

-

A Mad Idea Fueled by Gin

It started with Camp Tipsy. Alex and I started talking about what we could build, what kind of floating contraption would excite us. We were unequivocally unanimous in wanting something like a tiny cabin that floats. Something that we could escape to. Or maybe it started earlier. Maybe it started with the river floats. For…

-

Sketchy Napkin Plans

As with all great projects, this one started with a napkin drawing: While barrel floats have a long glorious history, we’ll probably do either pontoons or a full plywood-fiberglass hull. We won’t need any kind of keel with pontoons, but with a full hull, the keel is still an open question. Though apparently some…